TEMPERATURE REGULATION UNITS / CHILLER UNITS

This plant is a strategic part of the security printing process, crucial for maintaining excellent quality levels.

The temperature is controlled by water circulation in eight independent closed circuits (Roller duct 1, Roller duct 2, Roller duct 3, Roller duct 4, Roller duct 5, Chablon rollers, Collecting ink cylinder, Plate cylinder, Wiping cylinder.

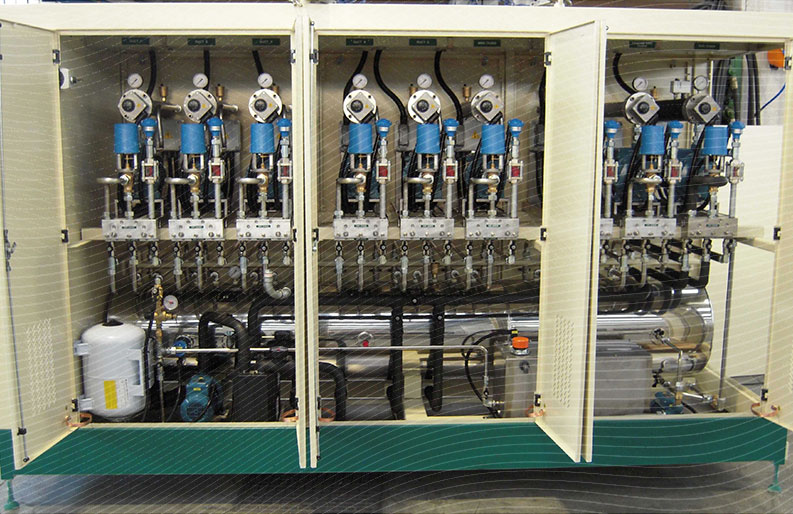

The unit consists of a metal cabinet containing:

- Water reservoir, capacity 350 l approx.

- Automatic filling valve, safety valve and expansion vessel.

- Heat exchanger for cooling in open circuit using water not exceeding 16°C (see remarks).

- Recycle pump between the tank and the heat exchanger for cooling.

- 9 thermoregulating modules.

- Electric control cabinet equipped with PLC type ABB-AC31 suitable for the Arcnet communication with the console of the printing machine in case of remote installation of the unit.

- Frontal panel equipped with Touch Screen for the control of the operation.

REMARKS

- In case the temperature of the available tap water exceeds 16°C, the unit should be connected with a centralized chilled water system, if available. If not, the unit is to be connected to a separate water chiller unit, air condensed, type CDR/EU 30.

- The unit is designed to work in conjunction with our Aqua Save II system and therefore does not contain either a reservoir or temperature control system for the wiping solution. If, for operational needs, different wiping solution temperatures are required for different printing machines then an auxiliary wiping solution tank is required.

- If the Aqua Save is located more than 50 m away from the machine, or if the heat loss due to the installation is too important, an auxiliary tank is to be foreseen in order to maintain the solution at the correct temperature.